Protection Strategies for Safeguarding Step-Down Transformers Against Faults

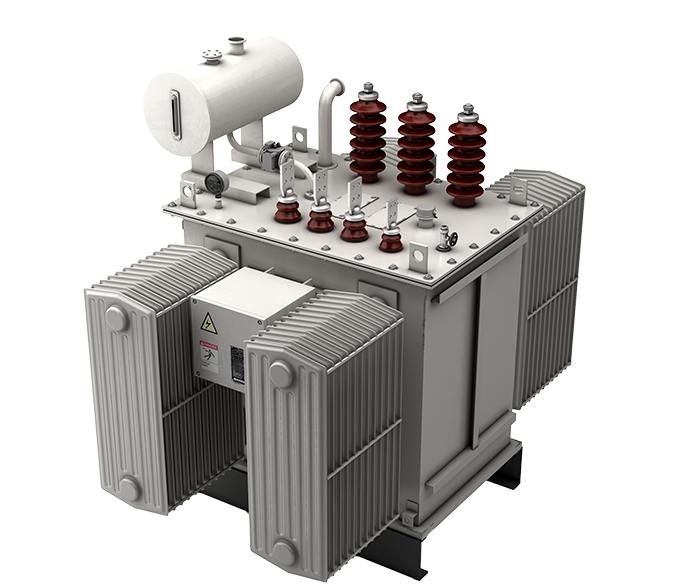

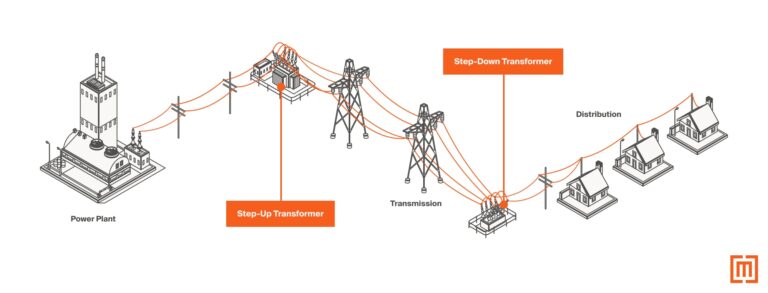

Electricity distribution involves a complex web of equipment that ensures power is reliably delivered to the end consumer. Step-down transformers play a crucial role in this system, reducing high-voltage electricity from power lines to levels that can be safely used in homes and businesses. However, these transformers are not immune to malfunctions, which can lead to power outages and pose safety risks. Here, we’ll explore how electrical engineers and energy sector professionals can develop robust protection strategies to prevent and address step-down transformer faults.

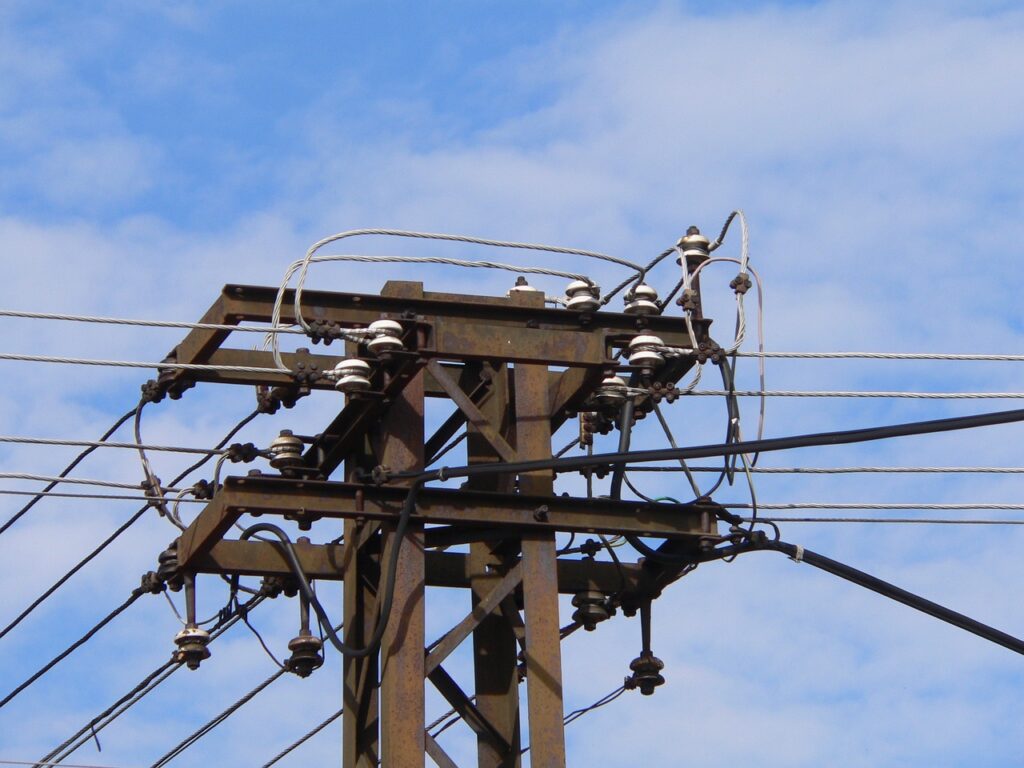

Understanding Step-Down Transformers

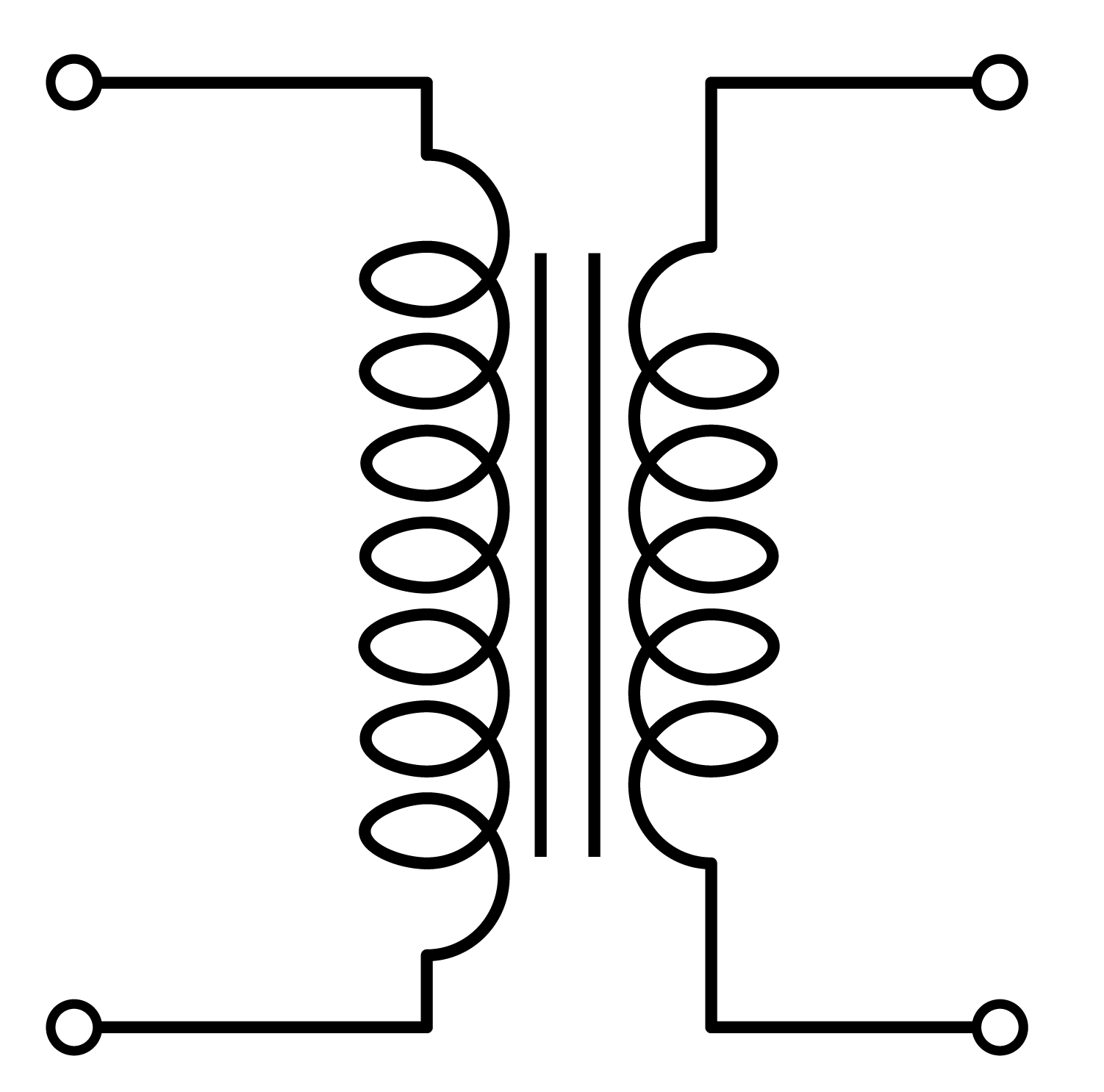

Step-down transformers are ubiquitous in the energy sector, serving as workhorses that enable the efficient transmission of electrical power. These devices utilize the principle of magnetic induction to convert electricity between higher and lower voltage levels. Key components of a step-down transformer include the primary and secondary winding, the core, and insulation systems. When analyzing protection strategies, it’s essential to have a fundamental understanding of their operation and the potential vulnerabilities within their design.

The Science Behind Step-Down Transformers

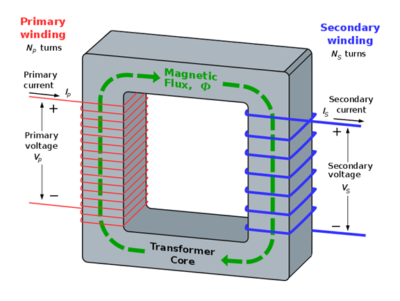

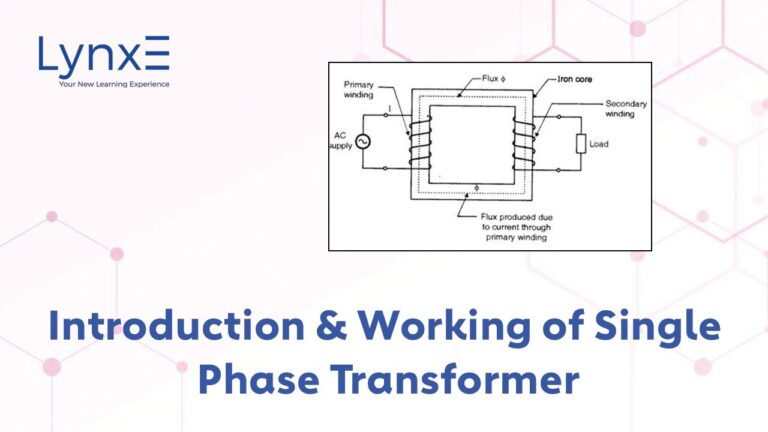

In essence, step-down transformers consist of two or more coils of insulated wire known as the primary and secondary windings. These windings are wrapped around a ferromagnetic core, typically made of iron or steel. When an alternating current passes through the primary winding, it creates a magnetic field around the core. The secondary winding is then able to ‘capture’ this field and generate its own AC current, which is usually of a lower voltage due to the differences in the winding ratios.

Components at Play

The core material and the number of turns in the primary versus the secondary winding determine the transformer’s output voltage. Together, the principal is simple, transforming voltage and current to allow for various power applications safely. Insulation in a transformer is also critical, as it must be designed to withstand the stresses of the electrical and thermal environment in which the transformer operates without degrading over time.

Common Faults and Their Causes

Transformers can suffer from a range of internal and external faults, each with its own set of causes and implications for the system’s performance. Knowing the signs of impending issues can help engineers intervene before a fault causes extended downtime or more severe problems.

Short Circuits and Overloads

Short circuits can occur due to insulation breakdown, overheating, or the growth of conductive particles in the oil surrounding the windings. An overload, on the other hand, happens when the transformer’s power rating is exceeded, typically from an excessive current flow. Both can lead to catastrophic failures if left uncontrolled.

Transformer Winding and Core Failures

Winding failures can be caused by elevated temperature, mechanical stress, or chemical contamination. Core problems are generally less common but can result from excessive stresses or magnetic imbalances.

Insulation Breakdown

Insulation breakdown can occur due to electrical stresses, moisture, or the presence of contaminants. When the insulation fails, high voltages can arc between the windings, leading to catastrophic transformer failure and potentially causing damage to the surrounding infrastructure.

Protection Strategies

Given the critical role step-down transformers play, it is imperative to implement protection strategies that can detect and respond to faults rapidly. There are several methods used in the industry, each tailored to address specific types of transformer faults.

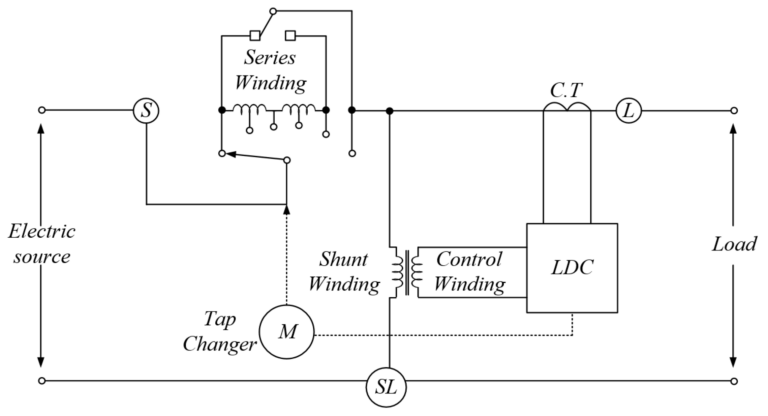

Differential Protection

Differential protection compares the current at the beginning and end of the transformer windings. If there is a significant difference, it indicates a fault, and the protection system isolates the transformer.

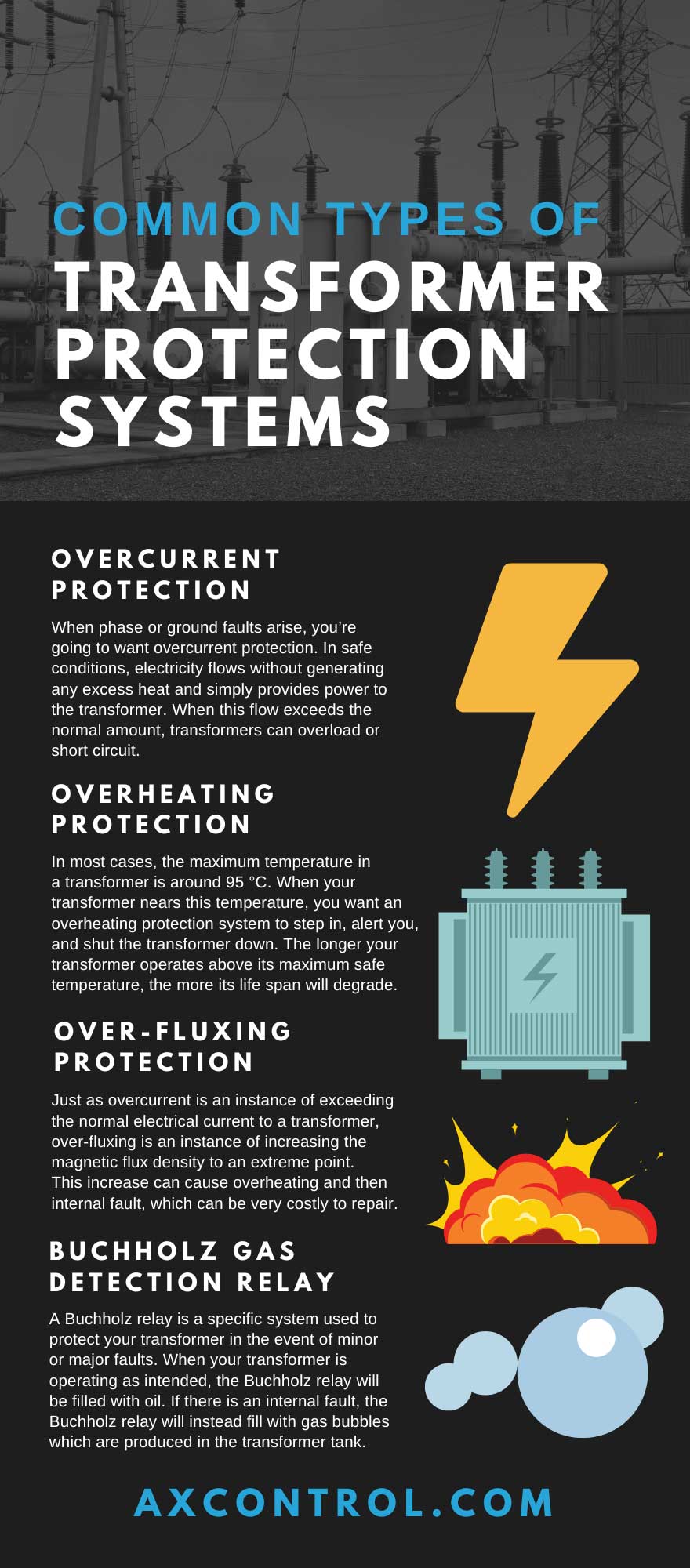

Overcurrent Protection

Overcurrent protection devices monitor the current flowing through the transformer. When current exceeds the pre-set limits due to a fault or overload, these devices trip to interrupt the power and protect the transformer.

Temperature Monitoring

Temperature sensors can be installed within the winding to monitor its temperature. An abnormal rise in temperature can be an early indicator of a fault, prompting a protective response.

Maintenance Best Practices

Preventive maintenance is the backbone of an effective protection strategy. Regular inspection and testing can identify potential issues before they escalate, ensuring that step-down transformers continue to operate safely and efficiently.

Inspection and Testing

Inspecting the transformer for signs of overheating, arcing, or leaks can provide valuable insights into its health. Routine testing of the oil and winding insulation can also help predict potential problems.

Oil Analysis

Oil is used as a coolant and insulator in many transformers. Regular analysis of the oil can detect signs of degradation, such as the presence of dissolved gases or the accumulation of solid by-products.

Online Monitoring

Modern transformers are often equipped with online monitoring systems that can continuously analyze the transformer’s performance and alert operators to any abnormal conditions.

The Future of Transformer Protection

The energy sector is constantly evolving, and so too are the technologies used to protect transformers. Emerging advances in sensor technology, data analytics, and artificial intelligence are poised to revolutionize how we safeguard these critical assets.

Sensor Fusion and AI

By combining data from multiple sensors and applying advanced algorithms, AI can predict and diagnose transformer faults with unprecedented accuracy, allowing for proactive maintenance.

Integrated Protection Systems

The future may see the integration of transformer protection systems with broader grid management solutions, enabling a more coordinated approach to power system protection and operation.

Nanotechnology and Smart Materials

Developments in nanotechnology may lead to the creation of ‘smart’ materials that can self-heal, providing an added layer of protection against common transformer faults.

Conclusion

Protecting step-down transformers requires a multi-faceted approach that includes understanding the equipment, recognizing potential faults, and implementing robust protection and maintenance strategies. Engineers and professionals within the energy sector must remain vigilant and adapt to the latest advancements to ensure the reliability and safety of our power networks.

As you build and enhance your knowledge of transformer protection, consider how you can apply these strategies in your professional setting. Electrical systems are as diverse as the industries they power, but the underlying principles of protection remain constant. Stay informed about the latest advancements, share knowledge within your networks, and continue to innovate. By doing so, you contribute to the durability and efficacy of the global energy infrastructure.

Share your experiences and insights with protecting step-down transformers — your story could inform and inspire others in the field. Engage in the ongoing conversation about transformer protection and consider how you might tackle the challenges that lie ahead. The future of energy protection is in your hands.